Product Details

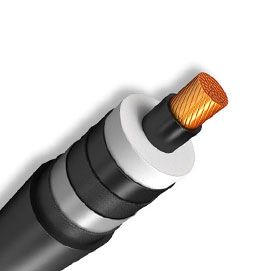

Teck 90 cable combination of interlocking flexible armour with two layers of PVC jacket provide a rugged, compact and flexible cable that is resistant to corrosion, water and mechanical abuse. It is designed for use in wet or dry locations with a maximum conductor temperature of 90˚C and a low temperature rating of -40°C.

Commercial applications for Teck cable include apartment buildings and commercial complexes. Teck cable is also an economical alternative as the need for conduits or ducts and pull boxes is eliminated.

Teck 90 cable is approved for use; in wet and dry locations, indoor and outdoor, in exposed and concealed wiring, in ventilated, non-ventilated and ladder type cable trays, for direct earth burial and for service entrance installations, above and below ground. It is ‘HL’ rated for use in all hazardous locations when used with optional 'HL' approved connectors.

•CSA C22.2 No. 131 for Teck cables rated up to and including 5kV

•CSA C68.10 for shielded Teck cables rated 5kV and above (C68.10 pending)

•CSA C22.2 No. 0.3 Clause 4.11.4 FT4 flame test

•CSA C22.2 No. 174 for use in the following hazardous locations (HL):

-Class 1 Group A, B, C, D. Division 1 & 2

-Class II Group E, F, G. Division 1 & 2

-Class III

•ICEA S-66-524 / NEMA WC7 for Teck cables rated above 5kV

•IEEE 383 &1202 (70,000 BTU/hr) flame test

•ICEA T-29-520 (210,000 BTU/hr) Vertical Cable Tray Flame Test

•ICEA T-30-520 (70,000 BTU/hr) Vertical Cable Tray Flame Test

*Refer to CE Code for details

Specifications

Low Voltage

UV Resistance

Medium Voltage

Water Resistance

Working Temperature 90℃

Cold Resistant -40℃

Flame Retardant

- Conductor:

Class B compact or compressed concentric stranded soft drawn bare copper per ASTM, conforming to CSA C68.3.

- Conductor Shielding:

A thermoset semi-conducting shield is extruded over the conductor on all cables rated over 1kV. Minimum thickness in accordance with CSA C68.3, Table 2.

- Insulation:

Cross-linked polyethylene (XLPE), meeting the requirements of CSA RW90 for cables rated up to and including 1kV. For cables rated 5kV and above, the TR-XLPE insulation meets the requirements of CSA Standard C68.3 M92.

- Metallic Shield:

A 15% gapped copper tape shield meeting the requirements of CSA C68.3 is helically applied to the insulated conductors in three conductor shielded cables rated 5kV and above. In single conductor cables, the concentric ground serves as the metallic shield and bonding conductor.

- Bonding (Ground) Conductor:

Class B stranded soft bare copper conductor, in accordance with CSA C68.3 and CSA C22.2 No. 131, is included in the assembled cable for multiconductor cables. In single conductor cables, the concentric ground serves as the metallic shield and bonding conductor.

- Fillers and Core Binder Tape:

Where required, suitable fillers to make round and core binders may be used.

- Inner Jacket:

Flame-retardant and moisture resistant PVC Jacket is applied over the core in accordance with CSA C22.2 No. 131.

- Armour:

Flame-retardant and moisture resistant PVC Jacket is applied over the core in accordance with CSA C22.2 No. 131.

- Outer Jacket:

A low temperature (-40°C), flame-retardant, moisture and sunlight resistant PVC jacket is applied over the armour in accordance with CSA C22.2 No. 131. Minimum thickness in accordance with CSA 68.3, Table 21. Complete cable FT4 rated.

- Colour Code:

TECK 90 CABLES:

•2 conductor cables are colour coded black and white

•3 conductor cables are colour coded black, red and blue

•4 conductor cables are colour coded black, red, blue and white

•5 or more conductor cables are black and alpha numeric coded

ARMOURED CONTROL:

•Conductor #1 is white, the remaining conductors are black and numbered - Options:

•Aluminum phase conductor and bonding conductor

•Ethylene-propylene rubber (EPR) insulation for shielded Teck cables rated 5kV and above •Overlapping copper tape shield

•Sequential marking on outer jacket

•Special ground wire requirements: 50% of phase conductor or more than one ground conductor

•Fully filled core for multiconductor Teck cables rated 5kV and above

•Galvanized steel interlocked armour (GSIA) for multiconductor Teck cables

•Coloured outer jacket

•Vertical riser Teck

•Variable frequency drive (VFD) Other constructions available upon request

- DEXIN CABLE

- UL CABLE

- UL 4703 Solar PV Cable

- Hook Up Wire - UL1015

- Teck 90 Cable

- Copper RW90 600V XLPE Insulation Cable

- SOOW Portable Power Cable

- Type THHN/THWN/T90 Wire

- Type AC(BX) Steel Armored Cable

- Nonmetallic-Sheathed Cable Type NM-B

- MC Cable With THHN Ground

- Nonmetallic-Sheathed Cable Certified for Canada Type NMD90

- Metal-clad Cable Certified for Canada Type AC90

- TC Tray Cable FR-XLPE/PVC

- SDW Cable

- Welding Cable 105°C 600V

- DLO Cable or Diesel Locomotive Cable

- CSA Foil Shield Fire Alarm Cable FAS Cable

- CSA RPVU90 RPV90 Solar Cable